choose your measurement

Chemical Concentration Meter

The Rhosonics CCM stands for Chemical Concentration Meter. This category of instruments allows measuring the concentration of chemicals and solutions in real-time. The CCMs (eg. B30 series) are designed to withstand many different chemicals and to match harsh process conditions.

Chemical Density Meter

The Chemical Density Meter offers real-time information about multiple parameters of liquids or slurries. The CDM is used for in-line measurement of TSS (Total Suspended Solids), TDS (Total Dissolved Solids) and density. Additionally, the sensor can withstand rough conditions of chemicals and mineral slurries thanks to the corrosion and abrasion-resistant sensor materials.

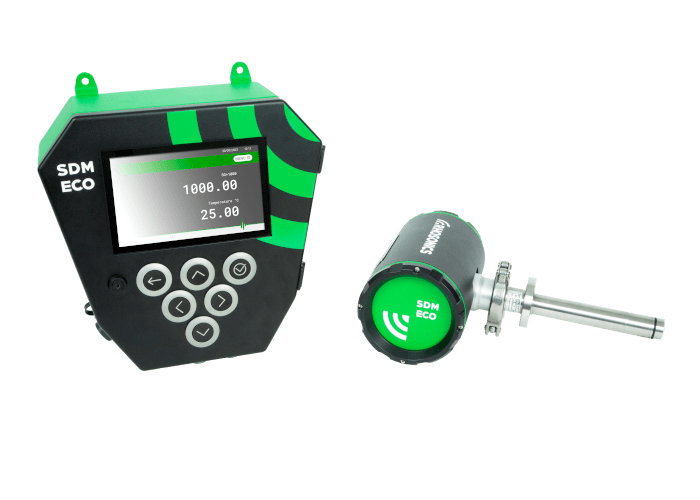

Slurry Density Meter

The non-nuclear Slurry Density Meter is suitable for real-time density measurement in all kinds of slurries. The product uses sustainable ultrasonic technology and is specifically designed for dredging and mineral processing applications. The SDM ECO uses a non-intrusive ultrasonic sensor to measure the real-time density of mineral slurries under high-density levels and at large pipes.

latest insights

InterBattery 2024

DS Linetech proudly showcased our latest innovation, the SDM ECO, demonstrating its capabilities and advancements to the attendees and industry professionals present at the event.

Rhosonics density meters at Beens Dredging

In a recent visit to Beens Dredging, Daniël from Customer Service and Frank from Marketing showcased the effectiveness of the Rhosonics density meters in dredging operations.

Product Discontinuation Notice

We would like to announce that as part of the exciting release of the SDM-ECO, our latest development, we have discontinued the SDM-4 as of January 2024.

about rhosonics