Measuring density in the flotation process

Monday 11 Dec 2023

Are you looking for a higher recovery rate in the Flotation process by means of automation and instrumentation? This blog describes the purposes and benefits of measuring density at different applications in froth flotation. First, the froth flotation process itself and control purposes are explained, then the first (of five) key reasons for measuring density will be given.

Full optimization for maximum recovery in the flotation process can only be achieved when a novel of instruments and analyzers are used together, such as density gauges, level gauges, flow meters, froth cameras, etc. This blog will show the importance of the Density meter, which is Rhosonics’ area of expertise.

The froth flotation process

In previous process stages, fine particles were created and valuable minerals were released from their carriers, also called the gangue. In general, flotation is used to separate and recover. The valuables are concentrated and separated from unwanted (gangue) particles.

This is done using chemicals and froth. This process exploits differences in surface properties between minerals and gangues. The froth flotation principle is a complex combination of the laws of surface chemistry, crystallography, and physics. Process efficiency depends on aspects such as density, electrical conductivity, and physical and chemical properties.

Without a flotation process, many metals and inorganic raw materials would be extremely scarce and expensive, as there are currently not many high-grade deposits that could be processed by simple physical and mechanical methods.

Purpose of process control

The main objective when controlling the flotation process is to maximize the quality of the throughput. An enriched product is created by decreasing the amount of gangue. To achieve these objectives the slurry needs to be continuously monitored and controlled, allowing process stabilization and ensuring optimal flotation conditions.

Measuring points

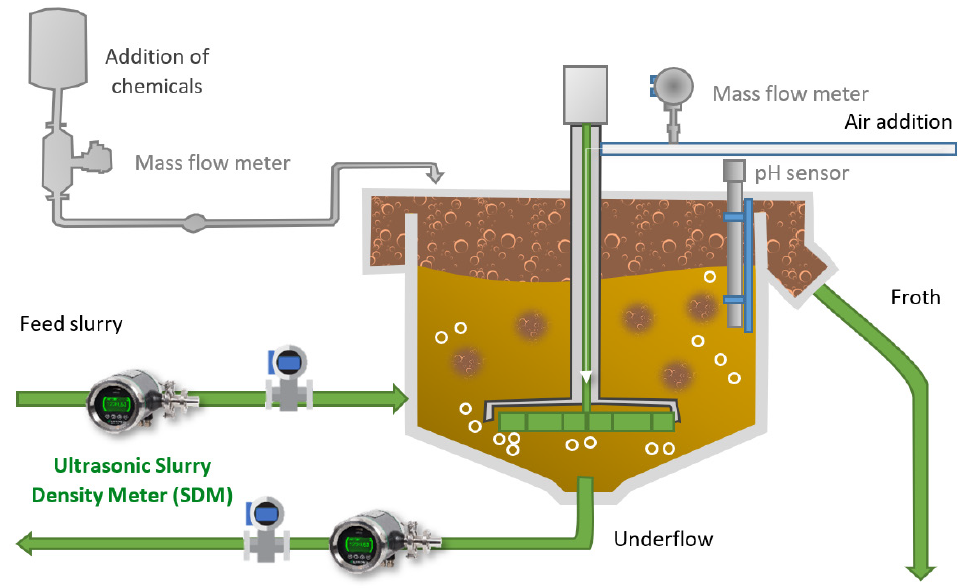

In the flotation cell, there are several possible installation points for density meters. For example in the feed slurry and tailings. Please check the overview of measuring points in the figure below.

The flotation cell overview of measuring applications

Why density measurement?

Instruments, such as density meters help the process personnel and operators to efficiently monitor and control the flotation process, optimize it and prevent process failures. When used together with an advanced control system, density readings allow for automatic control of valves and pumps and help to have an efficient chemical or air dosing, resulting in the improvement of the process that can lead to a higher enrichment and recovery of the desired mineral.

Measuring flotation feed

The density measurement in the flotation feed is a known installation point in mineral processing plants, and it is very important for mass balance. The combination of a density meter and a flow meter in the flotation feed and line of the final product of the flotation, not only allow for a mass balance calculation but also the calculation of the efficiency of the circuit.

Pulp and froth phases

The effect of flotation feed density on metallurgical performance has been investigated. Results of test work have shown that the pulp density affects key parameters of the flotation process in both the pulp and froth phases (Runge et al, 2012).

One of the findings was that froth phase recovery presumably improves because of a stabilizing effect due to a greater loading of solids on bubble surfaces. Additional research should be done to determine the optimum feed for a particular operation.

Prevent middlings

Particle size plays a crucial role in the enrichment of ore in the flotation process. The flotation operator wants to prevent middlings (a product that is neither a clean mineral product nor reject/tailings).

These middle-size particles consist of minerals and gangue. The gangue can only be separated from the valuable minerals in the flotation cells when the particles were grinded fine enough in previous stages.

The bubbles remove the fine particles

Real-time density measurement can help to verify changes in the slurry from the grinding circuit to the flotation cells. The slurry density has a high correlation with particle size, therefore the operator could use this parameter (together with other variables) to improve the control over the process.

space

Efficient enrichment

Optimal flotation means reducing the amount of gangue that is sent together with valuable minerals to further stages of the process. An enriched product should be produced with the lowest energy costs, containing the most valuable materials (the concentrate). Decreasing the amount of gangue can improve the quality of the concentrate.

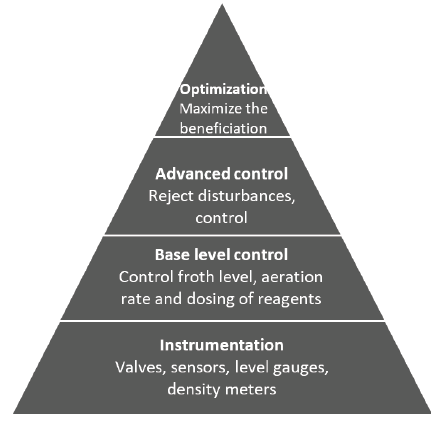

Instrumentation plays a crucial role in this enrichment process because it is the base for all process control. Automation can lead to a high level of performance in the circuit.

Besides density, the air injection and dosing of reagents should be monitored and controlled for efficient product enrichment. Smart air injection could solve problems with froth levels without using too many reagents.

The correct choice of instrumentation can only be achieved if a detailed understanding of the operation and application of the required instrument is acquired within a given process (Laurila et al., 2002).

Installing sensors is important, but the sensor itself will not guarantee continued performance. Having a skilled team is also essential. The flotation operator should be capable of interpreting and understanding the measurement data.

The operator is critical to make the most out of the collected process data. Advanced process control is needed to support the operator and to achieve good performances in the entire flotation circuit (Di Sandro, 2017).

Hierarchy in the flotation control system

Falling slurry level

The pulp level inside the cell can fall due to an increase in ore feeding (XinHai, 2020). In this case, the flotation operator should decrease the feed density, adjust grinding and classifying processes or adjust the reagent dosing or air injection to keep the slurry level at a certain point. An in-line density meter can be used to check in real-time the amount of ore in the feed (XinHai, 2020).

Flotation cells at a Moroccon processing plant

Ore piles up in the tank

One of the issues that can occur in the flotation process is that the ore in the flotation tank piles up (XinHai, 2020), this could have been caused by a too-high feed slurry solid content, which can be monitored in real-time by the use of a density meter.

Other reasons could be changes in pressure, a high inflating volume, and changes in the suction capacity of the suction tank. The flotation operator can use different tools to make the slurry flow again.

Available equipment

Density measurement is usually done by radiation-based measuring devices. This technology has been used in the mineral processing industry for decades. However, nowadays governmental regulations are getting stricter and associated costs are increasing. More nuclear density meters are being replaced by alternatives.

These alternatives can do the same job, without administration costs and health and safety risks related to the nuclear source.

Slurry Density Meter (SDM ECO)

The eco-friendly 3rd-gen Rhosonics Slurry Density Meter (SDM ECO) has been introduced in 2023 and preludes a new era of non-nuclear slurry density measurements. It is known as one of the best alternatives to radiometric density meters, with over 1.000 installations worldwide.

Conclusion

As discussed in our flotation blogs, measuring density in the flotation circuit is important. Density measurement can be used for advanced process control, preventing falling slurry levels and ore piling up in the tank and increasing the efficiency and recovery in the flotation process.

Together with flow measurement, the density can also be used for the mass balance, and to calculate the performance of the circuit.

More information?

Rhosonics has more than ten years of experience in using ultrasonic technology for non-nuclear density measurement in the mineral processing industry. We can help you to replace nuclear density gauges. Our density meters are used in different applications, such as ball mills, cyclones, flotation cells, and the thickening process.

Please contact Rhosonics if you want to learn more about density measurement in a non-nuclear way. Our team is ready to replace your nuclear density gauge.

Want to have frequent updates on our products? Then please subscribe to our newsletter or follow us on our social media accounts at LinkedIn, Twitter and Instagram.

Receive our technical update?

Fill in your name and email address and we’ll keep you in the loop on our latest technology updates.