The regulations for nuclear gauges

Wednesday 09 Mar 2022

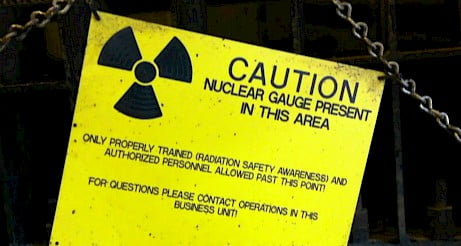

Are you struggling with regulations for your radiation source? You are not the only one. End-users in different industries are tired of all regulations for radiation-based gauges. This blog describes issues of nuclear regulations followed by a conclusion and a solution to solve these issues.

Why regulations?

Governments are implementing new rules for the use of radioactive sources and current rules are getting stricter. They have agreements with the International Atomic Energy Agency (IAEA). This is the world’s center for cooperation in the nuclear field. They seek to promote safe, secure and peaceful use of nuclear technologies. About 170 countries are members of this agency.

Member states have local nuclear agencies or commissions mandated by the governments to implement IAEA guidelines and regulations as part of an agreement signed by them. Not only governments, but also more and more companies are taking responsibility by implementing new ‘green’ policies with more care for the environment and safe working conditions.

The following five topics are highlighting common regulations and related issues.

1. Licenses and applications

In most countries, companies need to have a license for the use of nuclear sources. Local governments or nuclear agencies are responsible for publishing and maintaining a list of licenses, including details about the company, the location, the number of registered sources and the expiry date of the license. The license application brings an administration workload and costs. Without a license, it is hard to start using radiation-based measuring instruments.

2. Rules for disposal

What am I going to do with the old source? Most countries have companies which are offering disposal services. Also, most if not all countries with nuclear capabilities have signed treaties that say in part, if they manufacture Radioactive Material (RAM) they must also take responsibility for the disposal of it. This means that radioactive sources must return to the country of origin. This regulation helps to stop the dumping of radioactive material and it means that the RAM manufacturer must prepare to have the radioactive material returned to them for disposal. Transportation can be an issue if the source manufacturer is in another country.

3. Source disposal costs

Only authorized companies can help with the disposal of the source. Some licensees do not know where to go for disposal of the source and need to search for an authorized company or responsible authority to carry out the work. This could result in high costs, for example: between 2,000 – 7,000 US$ in the United States. This is only if there are no additional costs to solve safety problems with the radiation protection shielding. The company will check the sealing first to make sure that there is no leakage of RAM. Local disposal can lead to great expenses, therefore usually the industry is searching for a local RAM manufacturer with a good reputation and with capabilities to dispose of RAM that they manufacture. Click here to read more about the source disposal process.

4. Rules for inspections

Some countries mandate users of radiation sources to hire authorized companies to regularly inspect the outside of the source for radioactivity leakage.

A certified company takes samples from the radiation protection shield and shares the results with the client and local authorities. This inspection is also called a wipe test or a leak test. First, cover the surface of the protective shielding and clean it with an ethanol solution, then a cotton swab is used to check for surface contamination (e.g. with a cobalt-60 radioactive isotope). Records are reviewed and approved by inspectors and are kept for a certain period (e.g. three years).

5. RSO certification

Governments, agencies or commissions are responsible for conducting Radiation Safety Officer (RSO) courses. These regulations are part of IAEA guidelines and agreements.

Employees need training to handle radiation sources and safety procedures on site. They attend RSO training courses periodically, paid by the company. When an RSO leaves the company, a new employee needs training. At least one radiation safety officer needs to be on-site. If an RSO employee is temporarily unable to work, this could result in difficult situations.

Conclusion

There are a lot of regulations for companies who want to work with radiation sources. Before buying a radiation density gauge, the buyer should get advice by knowledgeable parties for the selection of RMA manufacturers with a good reputation to decrease the risks for high costs in the end.

Please note that the regulations can be different for each industry and region, depending on the restrictions of local governments. There are certainly more regulations and issues to mention and not all are included in this list.

Contact us if you recognize any of these regulation issues or if you want to know more about ultrasonic density measurement technology. Rhosonics helps the industry to eliminate costs and risks associated with the radiation source by offering ‘green’ solutions.

Want to have frequent updates on our products? Then please subscribe to our newsletter or follow us on our social media accounts at LinkedIn, Twitter and Instagram.

Receive our technical update?

Fill in your name and email address and we’ll keep you in the loop on our latest technology updates.